What is an Auger Drilling Machine?

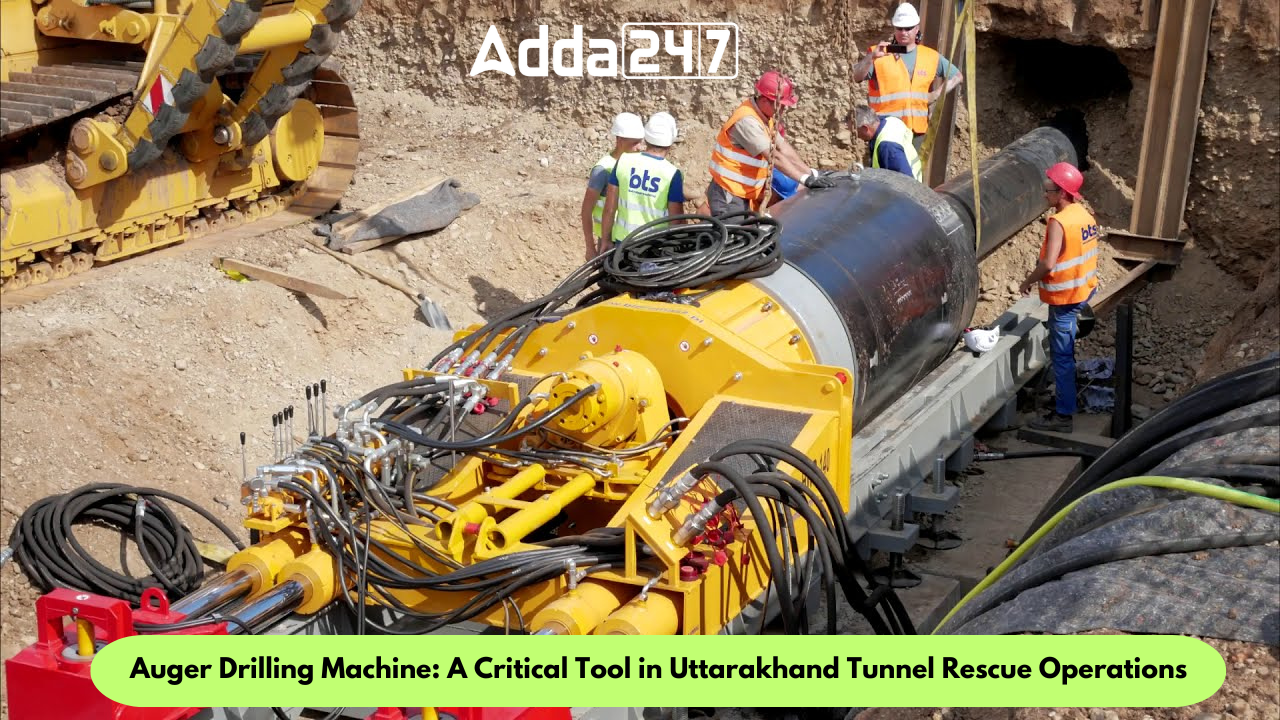

A horizontal auger machine, often called a horizontal boring machine or directional drill, is a specialized tool used to create horizontal bores or underground tunnels without disturbing the surface. It typically consists of a rotating helical screw blade called an auger, attached to a central shaft or drill, which penetrates the material by rotating. These machines are commonly employed in construction, utility installations such as laying pipes or cables, and infrastructure projects.

How Does an Auger Drilling Machine Work?

For the machine to work, it is positioned at the starting point of the bore, usually on the surface. It consists of a drill head with an auger or a drill string attached to it. The auger at the front of the machine rotates and cuts through the soil, rock, or other materials underground. Hydraulic or mechanical systems power this rotation.

As the auger advances, it removes the material from the tunnel, and it is usually flushed out by a drilling fluid or mud pumped through the drill string. This fluid serves to lubricate the drilling process, cool the cutting head, and carry excavated material back to the surface. The machine also has a steering system that allows operators to control the direction and angle of the bore.

Horizontal auger machines often use advanced guidance systems, such as GPS and electronic tracking, to ensure accuracy in direction and depth while drilling underground. Once the machine has bored the desired length, the auger is retrieved, and the tunnel is ready.

Types of Auger Drilling Machines:

Auger drilling machines come in various types, each designed for specific applications and soil conditions. Some common types include:

- Horizontal directional drills (HDDs): These machines are typically used for long-distance bores and can make turns in the bore path.

- Pipe augers: These machines are specifically designed for laying pipes or cables underground.

- Earth augers: These machines are smaller and more portable, making them suitable for smaller-scale projects, such as landscaping or post-hole digging.

Components of an Auger Drilling Machine:

A typical auger drilling machine consists of the following components:

- Auger head: The rotating part of the machine, consisting of a helical screw blade that cuts through the soil or rock.

- Drill string: The shaft that connects the auger head to the drive system.

- Drive system: The power source that rotates the auger head, typically powered by a hydraulic motor or an electric motor.

- Steering system: The mechanism that allows the operator to control the direction of the bore.

- Fluid system: A system for pumping drilling fluid or mud through the drill string to lubricate the cutting process, cool the auger head, and carry away excavated material.

Applications of Auger Drilling Machines:

Auger drilling machines are used in a wide variety of applications, including:

- Tunneling and underground construction: Creating horizontal bores for pipelines, cables, or other structures.

- Utility installation: Laying water mains, sewer lines, electrical cables, and other underground utilities.

- Foundation work: Creating anchor bolts and other foundations for structures.

- Landscaping: Digging post holes, planting trees, and creating irrigation ditches.

- Environmental remediation: Removing contaminated soil from underground.

Advantages of Auger Drilling Machines:

Auger drilling machines offer several advantages over other drilling methods, including:

- Reduced surface disturbance: They can create long, horizontal bores without disturbing the surface, making them suitable for urban or sensitive environments.

- Versatility: They can be used in a variety of soil conditions, including soft soils, hard rock, and mixed materials.

- Accuracy: Advanced guidance systems can ensure precise control of the bore direction and depth.

- Safety: They are generally safer than other drilling methods, as they do not require the use of heavy equipment or explosives.

Why Was an Auger Drilling Machine Used in the Silkyara-Barkot Tunnel Rescue Operation?

In the Silkyara-Barkot tunnel rescue operation, the initial plan to remove the debris blocking the tunnel exit using heavy excavators did not work. It was later decided that an auger machine could be a good option because if used properly, it can create a passage through the debris with minimum disturbance to the surface. To keep that passage intact, the rescuers are pushing 900 mm and 800 mm wide mild steel pipes along with the auger blade. Once the passage is complete, the auger blade could be pulled back from inside the pipes.

The use of an auger drilling machine in this case demonstrates its versatility and effectiveness in rescue operations. By carefully controlling the drilling process, rescuers were able to create a safe passage for the trapped workers without compromising the stability of the tunnel structure.

Find More General Studies News Here

Which Country is the Largest Producer of...

Which Country is the Largest Producer of...

Which Country is the Largest Olives Prod...

Which Country is the Largest Olives Prod...

Which City is known as the Apple Capital...

Which City is known as the Apple Capital...