Researchers at IIT Guwahati have created a fermentation process that uses ultrasound to safely generate Xylitol from sugarcane bagasse, the byproduct of crushing sugar cane. This approach gets over the operational constraints of chemical synthesis and the time lags of traditional fermentation. The use of ultrasound during the fermentation process not only reduced the time of fermentation to 15 hours, but also increased the yield of the product by almost 20%

Bank Maha Pack includes Live Batches, Test Series, Video Lectures & eBooks

Xylitol: Requirement for Safe Sweetners

- There has been an increase in the use of safe alternative sweeteners as awareness of the negative effects of white sugar (sucrose) on individuals with diabetes and general health has grown.

- A sugar alcohol generated from plants called xylitol may have anti-obesogenic and anti-diabetic properties in addition to being a mild prebiotic and guarding teeth against caries.

Xylitol: Research Team

- The research team includes Dr. Belachew Zegale Tizazu and Dr. Kuldeep Roy, who co-authored the research articles, and was headed by Professor VS Moholkar of the Department of Chemical Engineering at IIT Guwahati.

- Two peer-reviewed publications, Bioresource Technology and Ultrasonics Sonochemistry, both published this research.

- Advantages of this new procedure: The use of ultrasound during the fermentation process not only reduced the time of fermentation to 15 hours (as opposed to almost 48 hours in conventional processes), but also increased the yield of the product by almost 20%, according to Professor VS Moholkar, Department of Chemical Engineering, IIT Guwahati.

Xylitol: Resolving Current Sugar Substitute Problem

- In order to create xylitol industrially, D-xylose, a pricey chemical derived from wood, is processed with nickel catalyst at extremely high temperatures and pressures, which makes the process exceedingly energy-intensive.

- Only 8–15% of xylose is converted to xylitol, and the process involves numerous separation and purification steps, all of which translate to a high cost for the user.

- An appealing biological method to address these problems is fermentation. The process of fermentation is not new. Fermentation is the process used in many Indian families to turn milk into curd.

- In fermentation, many kinds of microbes, including bacteria and yeast, are used to change one material into another.

- The slowness of fermentation processes—the lengthy time it takes to turn milk into curd, for instance—creates a significant barrier to their use on a large scale in industry.

- To solve the aforementioned two issues, the IIT Guwahati researchers employed two strategies:

- First, they employed sugarcane bagasse as the raw material, which is the fibrous waste product left behind after extracting the sugarcane juice. This offers a way to upcycle a waste product and gets over the cost restrictions of the present xylitol synthesis techniques.

- Second, they employed a novel fermentation technique in which ultrasonic waves are used to speed up the microbe-induced synthesis of xylitol.

- The hemicellulose in bagasse was first hydrolyzed into five carbon (pentose) sugars like xylose and arabinose. They did this by chopping up the bagasse into tiny pieces and treating it with weak acid.

- The sugar solution was then concentrated, and fermentation was induced by adding Candida tropicalis, a type of yeast.

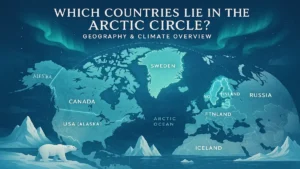

Which Countries Lie in the Arctic Circle...

Which Countries Lie in the Arctic Circle...

Gogabeel Lake in Bihar Declared Newest R...

Gogabeel Lake in Bihar Declared Newest R...

8th Pay Commission: What Is the Fitment ...

8th Pay Commission: What Is the Fitment ...